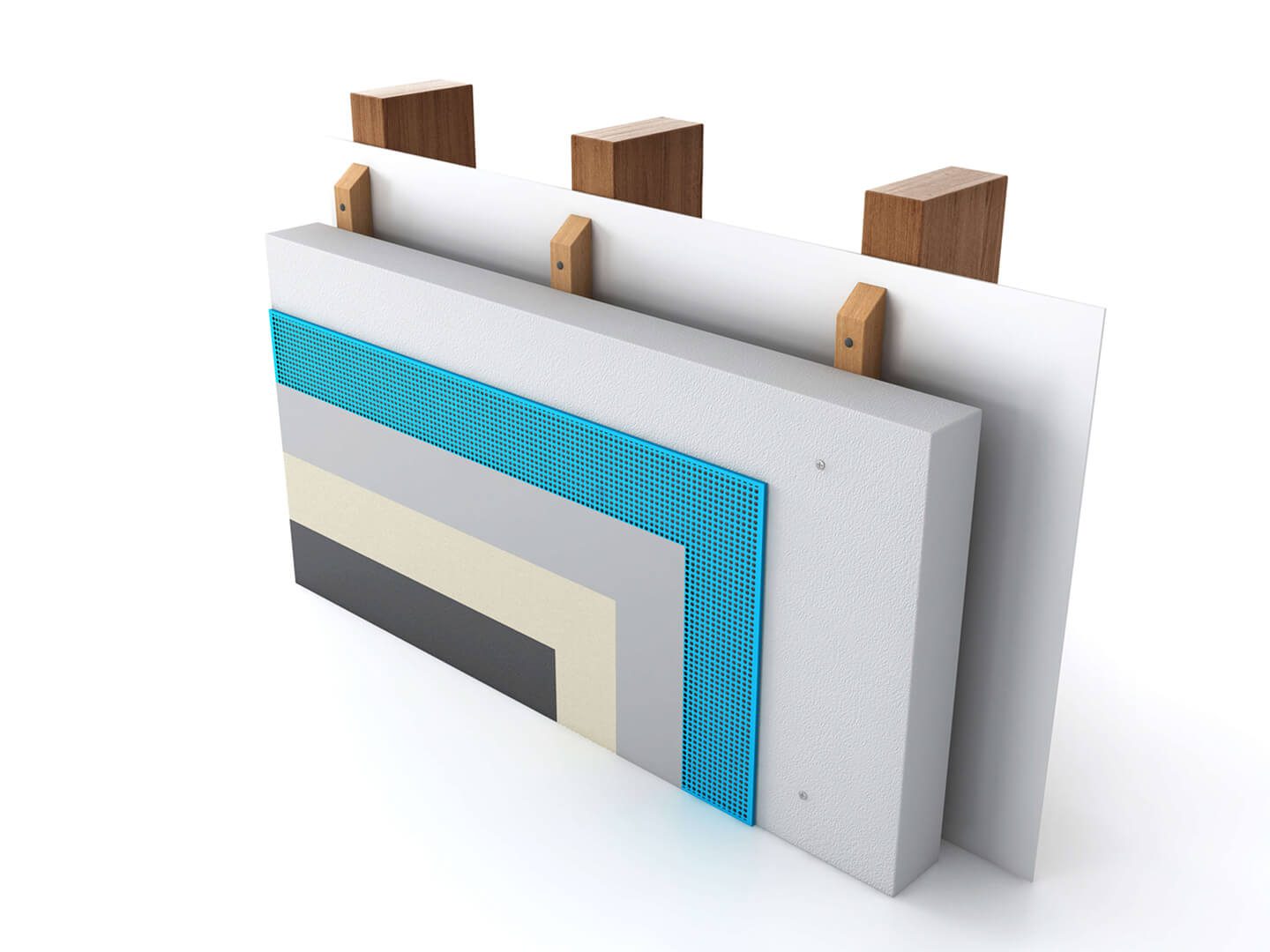

Celcrete 50mm AAC Panel Cavity System

The Celcrete System is a lightweight, durable AAC cladding solution engineered for New Zealand’s unique climate and building requirements. Fire-rated, weather-resistant, and low-maintenance, it provides seamless, high-performance exterior finishes that stand the test of time.

Designed for both residential and lightweight-commercial projects, Celcrete panels deliver exceptional thermal insulation, acoustic performance, and impact resistance, making them ideal for homes and architectural builds where every detail counts. The system is easy to install, reducing construction time while ensuring long-term durability and structural integrity.

With a range of plaster finishes and colour options, including Novacolor premium Venetian plaster, the Celcrete AAC Panel System allows architects and homeowners to achieve a modern, polished look or a textured, character-filled façade. Backed by BRANZ appraisal and NZ Building Code compliance, this system combines aesthetic versatility with trusted performance.

Whether you’re recladding, building new, or specifying a high-quality exterior finish, Celcrete delivers a cost-effective, sustainable, and architecturally trusted solution tailored to New Zealand conditions.

Documents and Brochures

Product Details

Fire Safety

Durable

CELCRETE is extremely durable and surpasses the minimum life as required by the NZ Building Code. CELCRETE AAC is extremely low maintenance and will not warp, rust or rot. The exterior cladding isn’t susceptible to decay or inspect damage and is allergen-free. Its strength also gives greater resistance to impact damage, so it can withstand any likely impact under normal conditions. The CELCRETE Panel Veneer System has proven to be extremely robust and resilient on Christchurch houses since the earthquakes of 2010 and 2011.

Economical

CELCRETE AAC is an especially economical product to use in construction. There are less components and fewer construction steps when using this cladding system compared to other construction methods. Therefore economies can be made that will reduce overall construction costs. This is particularly true when a building is specifically designed in modules that accommodate the dimensions of the cladding product. That way, on-site cutting and wastage can be significantly reduced. This approach also adds to the speed and simplicity of construction, further reducing costs.

Environmentally Friendly

CELCRETE AAC is an inert, natural and environmentally friendly construction material. Although it is made from minerals that are in abundant supply around the world, the manufacturing process makes very economic use of them and all trimming waste is recycled back into the production process.

There are no harmful pollutants generated by the production process, which is in itself very energy efficient.

Being inert the material is non-hazardous and does not emit any harmful gases or vapors.

Fire Resistant

Manufactured from non-combustible material, in case of fire it does not release toxic gases and smokes or drip burning material. With an ignitability of zero it greatly delays the spread of fire. Overseas tests show fire resistance ratings in excess of those required for residential or normal commercial buildings. CELCRETE AAC block construction has a fire rating of four hours for a 150mm thick load-bearing wall, the same ratings as for 200mm thick reinforced panels. A 100mm thick wall panel without any additional finishing materials has a fire rating of three hours.

Moisture Protection

The cellular structures of CELCRETE panel are comprised of many independent, closed, tiny and dispersed air spaces. Such a unique structure creates minimal water absorption and when used in conjunction with our 50mm Panel Veneer System and Rendertek Plaster System all requirements of E2.3.2 are met.

Sound Absorption & Insulation

CELCRETE AAC is proven to be an excellent acoustic insulation material by building a defense against external noise pollution. Its sound insulation value is greater that other materials of the same weight.

Strong

CELCRETE Panel is made from autoclaved aerated concrete (AAC) and consists of sand, lime, cement, gypsum, water and an expansion agent. When processed this expands up to five times to achieve a weight approximately 1/5 that of standard concrete. Strength is also provided by corrosion protected internal steel reinforcing mesh and when installed as part of the CELCRETE Panel Veneer System is guaranteed to meet NZ Building Code requirements.